Special Effects Wax (SFX)

Special Effects Wax or Modelling Wax started as a tool used by morticians to create lifelike appearances for the deceased. Today, it is used primarily in the cosmetic, movie and theatre industries to create realistic-looking injuries, deformities and other three-dimensional effects.

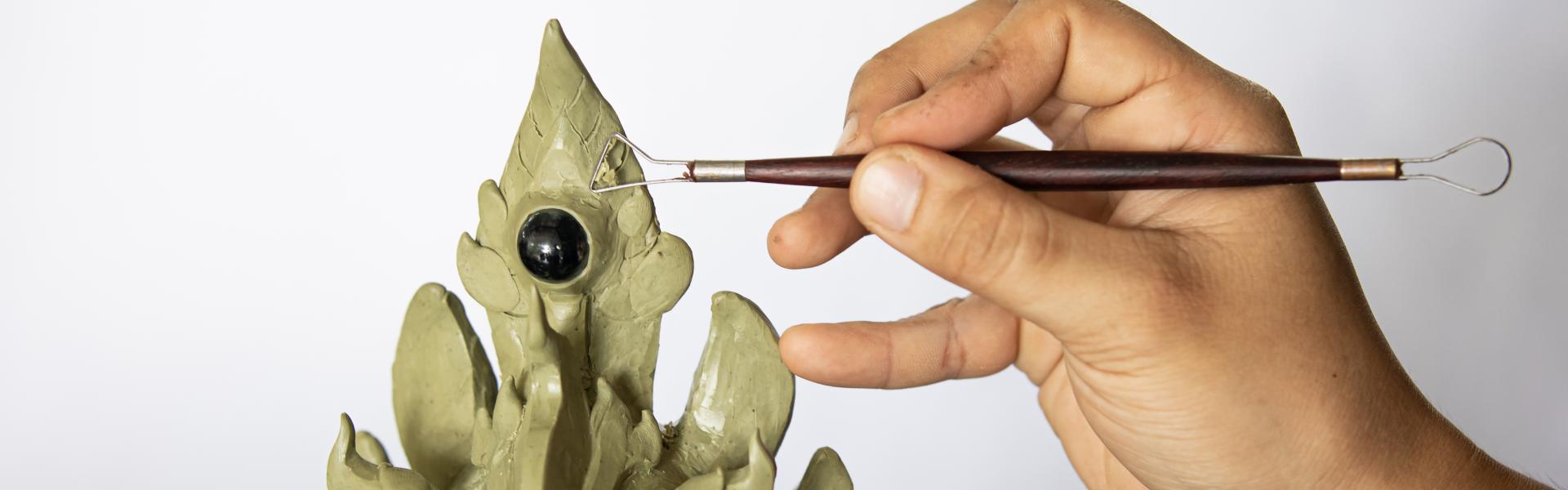

Renowned for its pliable, moldable, and adhesive properties, it is favoured by makeup artists to create realistic scars, wounds (bullet holes, burns), broken noses, ageing effects (wrinkles, sagging skin) and fantasy creature features (horns, scales, etc).

In this article, we will examine the composition and chemical properties of SFX wax, its key properties, manufacturing standards, quality control, and its applications in different industries.

The Chemical Properties and Composition of Special Effects Wax

SFX wax lacks a single “chemical structure.” Its unique properties are due to a blend of different components.

It is made up of the following:

- Microcrystalline wax: This is a refined petroleum wax comprising fine crystals recommended for blending and sculpting. It consists primarily of alkanes (saturated hydrocarbons) with carbon chain lengths typically ranging from C45 to C80, with a high melting point (60-90°C). These provide flexibility and adhesion.

- Paraffin wax: This is a more brittle petroleum wax with coarser crystals. It is often used with microcrystalline wax to modify hardness and melting point. Its chemical structure is similar to microcrystalline wax, consisting primarily of alkanes with carbon chain lengths typically ranging from C20 to C40, with a lower melting point (47-64°C). It is also more brittle and less adhesive than microcrystalline.

- Beeswax: With a melting point of around 62-64°C, this wax is sometimes added to enhance firmness and adhesion and provide a natural fragrance. It comprises a complex blend of esters, fatty acids, hydrocarbons, and alcohols, which give it its distinctive scent and good binding properties.

Oils and Emollients are added to make SFX wax soft, pliable and workable. These include:

- Mineral Oil (Paraffinum Liquidum): This petroleum-derived oil is odourless and colourless. It softens the wax and improves its blending properties.

- Petrolatum (Petroleum Jelly): Similar to mineral oil but adds emolliency and viscosity. It is soothing, forms a protective layer and locks in moisture.

- Vegetable Oils (Castor Oil, Almond Oil): These natural alternatives are primarily triglycerides (esters of glycerol and fatty acids), which provide softness and soothe skin. Emollients also have antioxidant properties.

Fillers or Texturizers are optional additives used to modify the texture or appearance of the wax. These may include:

- Titanium Dioxide (Tio2): A white pigment used to modify the opacity and whiteness of the wax by scattering light and reducing translucency.

- Clay (Kaolin, Bentonite): It is absorbent, adds bulk and creates a slightly matte texture.

- Starch (e.g., Cornstarch): A thickening agent that can absorb oils and reduce stickiness.

Adhesives/Tackifiers enhance the wax's ability to stick to the skin. Resin Esters such as Glyceryl Rosinate, derived from natural resins, are commonly used.

Colourants are also used to match skin tones or create specific effects. These include:

- Pigments (Iron Oxides, Ultramarines): These are insoluble colourants that are colourfast, stable and provide colour and opacity.

- Dyes (Oil-Soluble Dyes): These are soluble colourants that are less opaque than pigments and provide transparent colour.

Stabilisers or Preservatives are often added to improve shelf life. These include:

- Antioxidants such as Vitamin E that protect against free radicals and prevent oxidation. They also stop oils from turning rancid.

- Preservatives such as Parabens and Phenoxyethanol prevent microbial growth.

Key Properties of SFX Wax

Special effects wax is an unassuming material that is the foundation of realistic, bizarre, horrific, or captivating creations. Understanding its workability, adhesion, sculpting potential, and reaction to different conditions will unlock your ability to transform imaginations into tangible realities.

Here are some of its special properties, which make it a versatile tool for artists of all skill levels.

- Malleability: Allows for easy shaping and moulding.

- Adhesion: It sticks well to the skin.

- Sculptability: It holds its shape during application and performance.

- Blendability: It can be seamlessly blended into the skin.

- Flexibility: It can conform to movement without cracking or crumbling.

- Colourability: Pigments and dyes can be added to provide realistic colouring.

- Texture: Can be modified to create different surface effects (smooth, rough, etc.).

- Melting Point: This is low enough to be softened by hand warmth but high enough to remain stable at room temperature.

- Non-Toxic/Skin-Safe: Ingredients are safe for prolonged skin contact.

- Shelf-Life: Stable to resist degradation, drying out, or rancidity over time.

Raw Material Requirements

Good quality raw materials are essential for the performance and safety of SFX wax. Factors worth considering are:

- Purity: Product impurities can impact colour, odour, texture, and skin safety. Waxes and oils must be highly refined and free from contaminants.

- Consistency: Every batch of raw materials should be consistent in melting point, colour, and other key properties.

- Skin Safety: Every ingredient should be cosmetic-grade and approved for use in skin products. Compliance with regulations like the FDA (in the US) or the EU Cosmetics Regulation is imperative.

- Sourcing: Responsible sourcing involves conserving the environment in manufacturing and producing raw materials. It also includes ethical labour practices.

To ensure consistency, safety, and performance, strict quality control measures must be implemented during the manufacturing process. General quality control tests include:

- Visual inspection examines the colour, texture, and visible impurities.

- Determining the melting point ensures the wax melts within the specified temperature range.

- Testing the adhesion determines how well the wax sticks to a standardised skin substrate.

- Colour matching ensures that the wax matches the target colour standard. This can be done visually or using a spectrophotometer.

- Stability testing assesses the long-term stability of the wax by exposing it to high temperatures and humidity.

- Rheological testing measures the flow and deformation properties of the wax to assess its behaviour during application and sculpting.

- pH Testing measures the acidity or alkalinity, ensuring a skin-friendly product.

- Heavy metal testing ensures compliance with regulations limiting the presence of heavy metals.

Professional Applications in Industry

Special effects wax is a versatile and crucial material in the film, television, and theatrical industries. It enables artists to create realistic and believable illusions. It is professionally used to sculpt prosthetics, blend edges of pre-made appliances, build up features for ageing or injury makeup, and even simulate flesh wounds.

Here are a few of its applications in industry:

- Film and Television: It is used extensively to create realistic injuries, deformities, and ageing effects for actors in movies and TV shows.

- Theatre: It serves a similar function as film and television, frequently with more exaggerated effects for the stage.

- Cosmetics Industry (Prosthetics): SFX wax is sometimes used here as a base for creating small prosthetic pieces.

- Haunted attractions and theme parks: For special effects like bizarre creatures or cartoon characters.

- Training or Education: Medical schools and Emergency Response training programs use SFX wax to create realistic simulations of injuries for training purposes (e.g., moulage). It also builds models for forensic reconstruction or demonstration.

- Fashion and editorial photography: The wax creates unique and dramatic makeup looks.

- Special events such as Halloween: SFX wax is used to create costumes and special effects makeup.

Important Considerations:

- Although considered skin-safe, a patch test is always recommended before applying SFX wax to a large area of your skin.

- SFX wax may be removed with a makeup remover or oil-based cleanser.

- It should be stored in a cool, dry place away from direct sunlight to prevent melting or degradation.

Wrap Up

Special effects wax is a versatile wax blend of waxes, oil, and other additives. Its properties include pliability, adhesion, and a credible, true-to-life appearance that make it perfect for various cosmetic, medical, and entertainment uses. Good-quality raw materials and vigilant quality control are imperative to guarantee safety and performance.

Plant: Strada Quaglia, 26 - 10026, Santena (TO)

Offices: NEXTTO Polo Uffici Lingotto

Plant: Strada Quaglia, 26 - 10026, Santena (TO)

Offices: NEXTTO Polo Uffici Lingotto Group Company

Group Company